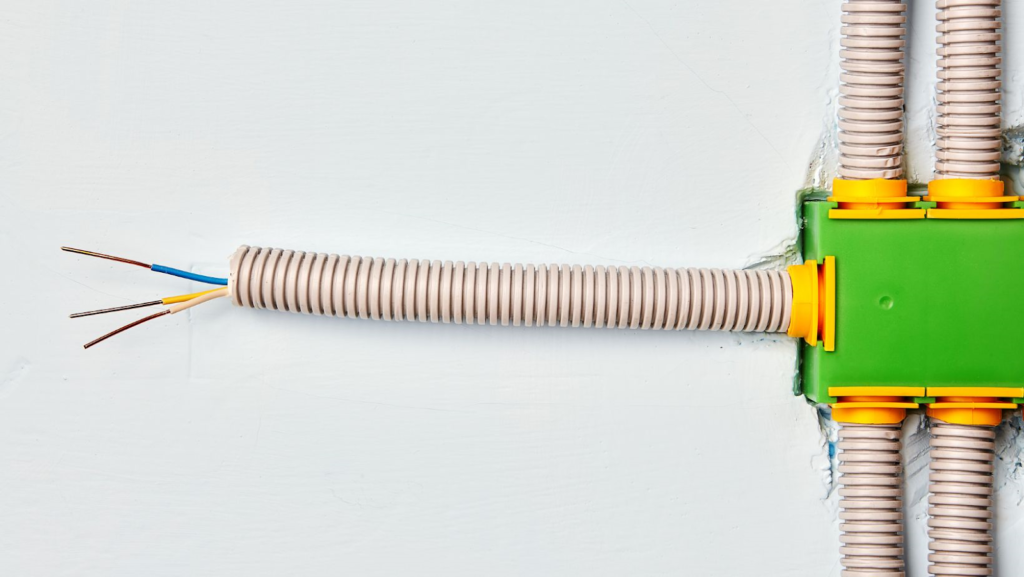

Electrical conduits are foundational to modern electrical installations, providing protective pathways for electrical wiring. These tubes, often made of metal, plastic, or fibre, ensure that electrical wires are shielded from potential damage, external environmental factors, and accidental contact.

Beyond the evident safeguarding benefits, there’s another pivotal aspect to consider: size.

Selecting the appropriate conduit size isn’t just about ensuring a snug fit for your wires; it’s crucial for maintaining electrical safety and adhering to established codes and standards.

The question then arises, “What size conduit is appropriate for 8/3 wire?”

This article delves into this query, underscoring the significance of making an informed choice for both safety and compliance. But before we dive deeper into answering this query, let’s discuss the basic terms and definitions you may know to understand the topic clearly.

Basic Terms and Definitions

Wire Gauge:

At the core of any electrical installation is the wire itself, and its gauge is a crucial determinant of its capacity and purpose. The term “8/3 wire” refers to a specific wire size and composition. The “8” represents the American Wire Gauge (AWG) size, indicating the thickness of the wire. As the AWG number decreases, the wire diameter increases. The “3” signifies the number of conductors within the wire, not including any grounding wire. So, an 8/3 wire typically consists of three insulated conductors, each being of 8-gauge thickness, plus a grounding wire.

Conduit:

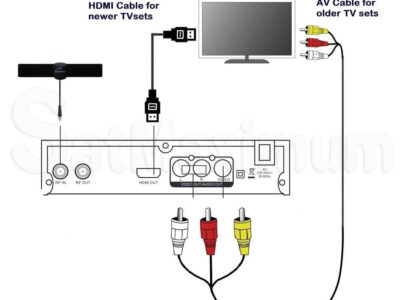

A conduit is a protective tube that houses and protects electrical wires from external damage and potential hazards and offers a structured routing mechanism. Various materials and types of conduits are available, such as EMT (Electrical Metallic Tubing), PVC (Polyvinyl Chloride), and RMC (Rigid Metal Conduit), and each comes with its distinct applications and benefits.

Fill Capacity:

Every conduit has a specified fill capacity, which refers to the maximum amount of space that the enclosed wires can occupy inside the conduit. This capacity ensures that wires have sufficient space to dissipate heat and can be safely and easily pulled through the conduit during installation. The National Electrical Code (NEC) provides guidelines on the percentage of conduit fill permitted based on the number and type of wires within, ensuring safety and functionality in electrical systems.

What Size Conduit for 8/3 Wire?

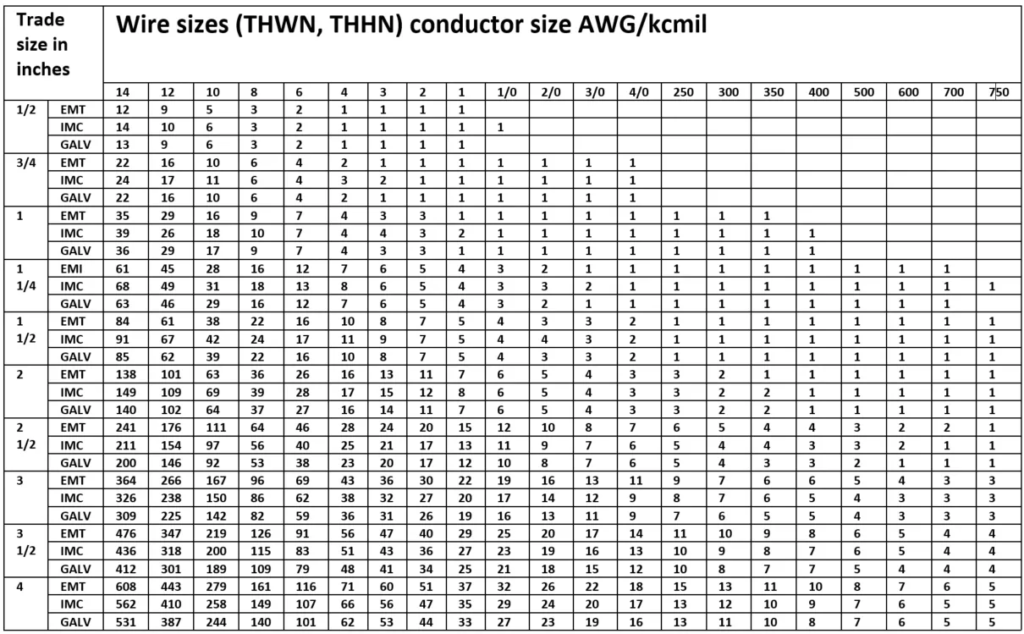

The chart below shows the conduit size for 8/3 wire, various other conduit sizes, and different wires. The number changes as the wire size and conduit type change. You can check according to your requirements:

Is It Necessary For 8 Gauge Wire To Be Enclosed In A Conduit?

An 8 gauge wire does not necessarily need to be in a conduit; it largely depends on the specific circumstances and local building codes.

Generally, wires are placed in conduits in residential and indoor settings to protect them from physical damage and safeguard the surroundings from potential fire hazards. Using a conduit is usually recommended for outdoor installations or in areas where the wire could potentially be damaged.

However, for applications like direct burial, there are types of 8 gauge wire specifically designed to be used without conduit. It is always best to consult the local building codes or a professional electrician to ensure compliance with safety regulations.

Determining The Correct Size Conduit – Some Important Factors To Choose The Size Of The Conduit

Determining the correct conduit size for an 8-gauge wire involves considering several factors. Let’s delve into each factor in detail:

1- Wire Type:

The type of wire, whether solid or stranded, plays a pivotal role in electrical installations.

Stranded wires, composed of multiple small strands, offer greater flexibility than their solid counterparts, making them preferable for routing through tight spaces or bends within conduits. However, this flexibility comes with a trade-off.

The inherent air gaps between the individual strands in stranded wires can cause them to occupy more space within the conduit than a solid wire of equivalent gauge. Beyond the wire’s core structure, the insulation type and thickness significantly influence conduit fill.

Common insulations include THHN (Thermoplastic High Heat-resistant Nylon-coated), THWN (Thermoplastic Heat and Water-resistant Nylon-coated), and XHHW (Cross-Linked High Heat-resistant Water-resistant), which cater to diverse environmental conditions and usage needs.

Each type of insulation not only contributes to the wire’s overall diameter but also dictates its thermal properties and resilience against external factors. For instance, the water-resistant nature of THWN makes it apt for damp environments or subterranean installations.

Collectively, these attributes—wire structure and insulation specifics—must be considered meticulously to ensure optimal wire performance, safety, and longevity while determining the appropriate conduit size for any electrical project.

2- Number of Conductors:

The National Electrical Code (NEC) sets a conduit fill capacity, which is the maximum amount of space that the conductors can occupy within the conduit. For example, if you’re running three or more current-carrying conductors, they can only fill 40% of the conduit’s cross-sectional area.

The more wires you place in a conduit, the larger the conduit you’ll need to ensure safe heat dissipation and to prevent wire damage.

3- Conduit Material:

- PVC: Typically used for underground or above-ground installations where durability against moisture or corrosive conditions is needed. Its interior can be more frictional, so consider wire-pulling ease.

- EMT (Electrical Metallic Tubing): Common for indoor use, lightweight, and often used for exposed locations.

- Rigid Metal (RMC): Heavy-duty conduit that can be used underground with proper sealing. It offers excellent protection and grounding.

- IMC (Intermediate Metal Conduit): Lighter than RMC but provides good protection. Commonly used for exposed areas.

Due to wall thickness differences, each material has different internal diameters for the same nominal conduit size.

4- Ambient Temperature & Heat Dissipation:

Wires generate heat when electricity passes through them. If the surrounding environment is already hot or lacks airflow, you might need a larger conduit to dissipate heat effectively.

Heat can degrade wire insulation over time, so ensuring adequate space for heat dissipation is crucial.

5- Bending & Pulling:

If your installation has many bends, turns, or long runs, consider upsizing the conduit. This makes pulling wires through easier and reduces the risk of damaging the wires.

6- Future Expansion:

If there’s a possibility you might add more wires in the future, select a larger conduit size to accommodate potential additions.

7- Local Building & Electrical Codes:

Always consult the local codes because they might have specific requirements or guidelines for conduit sizing.

When choosing a conduit size, a good rule of thumb is to never exceed 40% of the conduit’s total cross-sectional area when pulling more than two conductors. Referencing conduit fill tables based on the NEC can be invaluable for conduit fill calculations. However, for the best results and to ensure safety and compliance, consider consulting with a licensed electrician or electrical engineer.

Installation Tips

- Ensuring Smooth Pulling of Wire Through Conduit:

One of the primary challenges during wire installation is the pulling process. A smooth transition is vital to prevent any damage to the wire insulation, which can compromise the entire system.

To facilitate this, it’s advisable to use a wire-pulling lubricant. This specialized lubricant diminishes the friction between the wires and the conduit’s interior, allowing for an easier and more efficient pull.

Additionally, adhering to the National Electrical Code (NEC) guidelines on conduit fill capacity is of the essence. Overfilling conduits can not only make wire pulling strenuous but also increase the risk of insulation wear and tear.

For those especially challenging pulls, incorporating pulling grips can be a game-changer. These are tools ingeniously designed to hold wires securely, ensuring an even force distribution during the pull and preventing wire damage.

- Importance of Using Appropriate Fittings and Connectors:

The integrity of an electrical installation doesn’t solely depend on the wires and conduits but also on the fittings and connectors. These seemingly minor components play a pivotal role in ensuring a safe and long-lasting installation.

Choosing the right fittings and connectors tailored to the wire type and conduit material is crucial. They not only provide a secure connection but also prevent potential disconnections, short circuits, or grounding issues.

Additionally, the right connectors safeguard the wire insulation from sharp conduit edges, further ensuring the longevity and safety of the installation.

- Recommendations on Conduit Bending and Placement:

The art of conduit installation lies not just in threading wires but also in the conduit’s bending and placement. Proper conduit bending is imperative. It ensures that there’s no undue stress on the wire, prevents kinking, and maintains a neat and organized appearance.

Using dedicated conduit bending tools can make the task more precise. As for placement, strategic positioning of the conduit is essential. It should be routed in a manner that offers maximum protection from potential external hazards, be it environmental factors or physical disturbances.

Considering future maintenance or system upgrades during initial placement can save significant time and effort in the long run.

Conclusion

In determining the appropriate conduit size for 8/3 wire, various factors play a pivotal role, from the wire’s physical dimensions to local electrical codes. It’s essential to consider not only the wire’s current requirements but also any future modifications or additions that might arise. Utilizing conduits that offer ample space ensures ease of installation, reduces the risk of wire damage, and facilitates efficient heat dissipation. Always consult the National Electrical Code (NEC) and local regulations to guarantee compliance. Furthermore, seeking guidance from a licensed electrician or an electrical engineer can provide clarity and assurance in making the right choice for both safety and performance.